Our Virtual Copy: Digital Twins

Our Virtual Copy: Digital Twins

A digital twin is a living and intelligent digital representation of physical objects, systems or processes. It is alive as it works in real time; it is smart as it can make decisions on behalf of the physical entity and automatically implement those decisions.

Before we get into the details of the digital twin technology, let's go back a bit.

“Houston, we’ve had a problem”

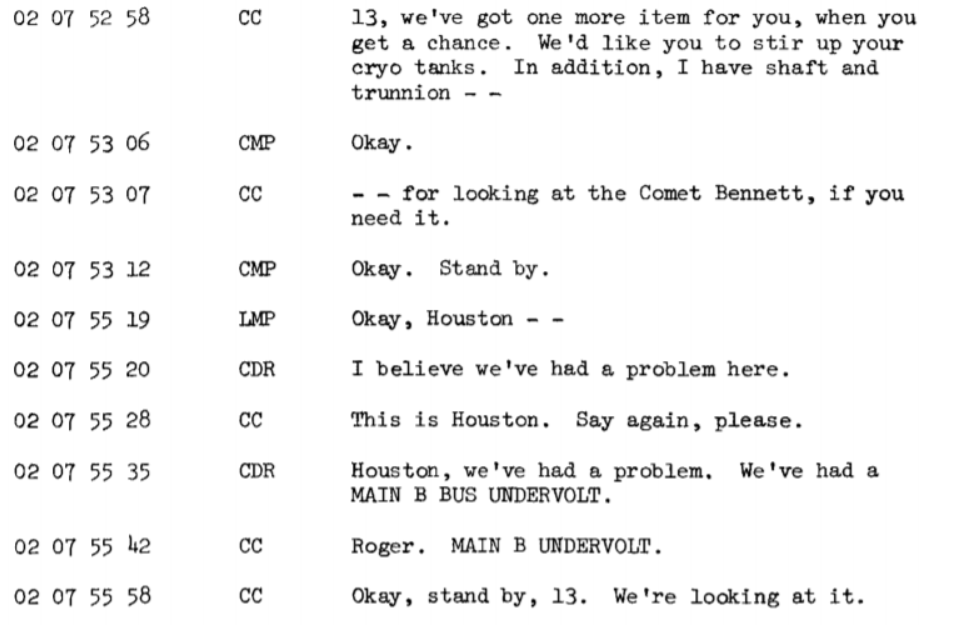

.png) The first simple application of the twin system idea, which forms the basis of the digital twin concept, is accepted as the solution method used in an event that we are familiar with.The date is April 11, 1970. NASA launches the spacecraft with 3 astronauts as part of the 7th manned space mission and the 3rd manned Moon mission, Apollo-13, at the beginning everything seems to be fine. However, 2 days after the launch, an explosion in the Apollo-13 spacecraft, about 320,000 km from Earth, seriously damaged the oxygen cylinders and leaked most of the oxygen sources into space.The astronauts report this critical problem to the Houston mission center with a dialogue that begins with the famous phrase "Houston, we've had a problem.”

The first simple application of the twin system idea, which forms the basis of the digital twin concept, is accepted as the solution method used in an event that we are familiar with.The date is April 11, 1970. NASA launches the spacecraft with 3 astronauts as part of the 7th manned space mission and the 3rd manned Moon mission, Apollo-13, at the beginning everything seems to be fine. However, 2 days after the launch, an explosion in the Apollo-13 spacecraft, about 320,000 km from Earth, seriously damaged the oxygen cylinders and leaked most of the oxygen sources into space.The astronauts report this critical problem to the Houston mission center with a dialogue that begins with the famous phrase "Houston, we've had a problem.”

After this notification, busy hours begin in Houston in order to return the Apollo 13 astronauts to their homes safely. The idea of using advanced simulation environments that astronauts normally use in their training processes is the beginning of the solution. The current situation is simulated by the current status information they receive from the Apollo 13 astronauts. Innovative solutions are produced based on the simulation results and the necessary commands for the implementation of the solution are reported to the astronauts. At the end of the day, with the cooperation of the mission center and the astronauts, the astronauts were able to set foot on our planet again.

This event, which is known as "successful failure" in history, can be considered as the first application of the digital twin, which has not yet been named, since there is a physical system (spacecraft), a virtual replica (simulator) and an information flow between the two, even if it is manual.

On the other hand, the concept of digital twin was first put forward in 2002 by Michael Grieves from the University of Michigan and John Vickers from NASA. The digital twin mentioned here is based on the idea of having a virtual representation of each product within the scope of Product Lifecycle Management in the industry and establishing a two-way connection between the physical product and the virtual product.

Today's Digital Twin

With the development of key technologies such as the internet of things , cyber-physical systems, machine learning, big data, edge computing, the scope and usage area of the digital twin concept has expanded and has become one of the important technologies applied today.

With the increasing complexity in the systems and the decreasing level of predictability, the need to monitor the systems globally and take real-time action according to the instant situation has been the driving force in the development of digital twins.

In addition to remote and real-time monitoring of the systems, predictive maintenance activities are carried out and digital twins are used to determine the optimum time for maintenance. On the other hand, testing extreme scenarios in complex and costly systems is difficult, costly, and sometimes even impossible. Digital twins can enable these extreme scenarios to be simulated with real data.

Digital Twin Structure

The digital twin basically consists of 3 components: physical asset, virtual asset and real-time bilateral information flow. The data collected in the physical entity is transferred to the virtual asset in real time, the solutions and control strategies obtained from the operations such as simulation, estimation, optimization on the virtual side are transferred to the physical asset and necessary actions are taken in the real world.

The virtual entity that represents the physical entity can be a mechanism model such as a 3D model or a mathematical model, or a learning model developed with machine learning or a combination of the two can be a hybrid model. The aim here is to represent a certain aspect (dynamic, structural, etc.) within the specified requirements rather than presenting the exact same physical structure.

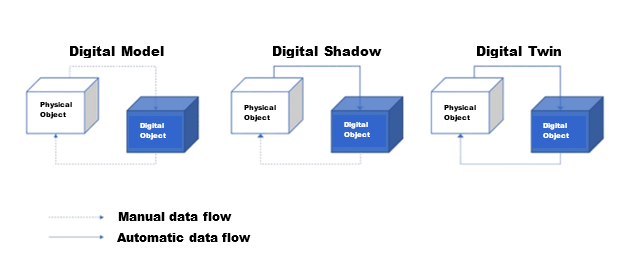

The levels of integration between physical and virtual assets are defined as:

Digital Model: It is the digital version of the physical asset. The information flow between the physical object and the digital object is provided manually.

Digital Shadow: While automatic data flow is provided from the physical asset to the virtual asset, the information flow from the virtual asset to the physical asset proceeds manually.

Digital Twin: It is an integrated system in which physical asset and digital asset interact automatically in two ways.

Types of Digital Twins

It includes different types depending on the characteristics of the physical entity it represents. In the case of the representation of an object, it is called "Product Digital Twin", while the concept of "System Digital Twin" is used for the representation of a system consisting of different objects in interaction. On the other hand, digital twins of processes can be created, and such twins are called “Process Digital Twins”.

Another classification is made according to the availability of physical assets. Before a physical product is produced, the twins that contain 3D models, material and service lists in the digital twin concept are defined as "Digital Twin Prototype", and the twins that ensure the verification of a manufactured physical asset by accompanying it throughout its lifecycle are defined as "Digital Twin Instance". The more comprehensive twins, which are formed by the combination of different digital twin samples, are called “Digital Twin Aggregation”.

Scope of application

Digital twin applications are in many sectors such as manufacturing, logistics, health, aviation, city, transportation and energy. Manufacturing, energy, health and aviation sectors can be mentioned as the most prominent sectors.

The live models developed with the data collected by sensors from CNC machines used in the manufacturing industry are a good example of the product digital twin. In addition, digital twins can be created for the products produced, for example, TESLA creates a digital twin for each vehicle it produces, and in this way, it can offer the predictive maintenance of the vehicles it sells to its customers as a service. On the other hand, process digital twins can be developed for real-time simulation and optimization of production and logistics processes.

As an example of digital twin applications in the health sector, we can talk about learning models developed by using features extracted from electrocardiographs and used in the diagnosis of various diseases. Many companies in the aviation sector such as BOEING, GENERAL ELECTRIC, LUFTHANSA create added value for themselves and their customers by using digital twin technology in fleet management, engineering design activities and predictive maintenance applications.

Within the scope of smart cities, digital twin technology is used in planning the actions taken for the COVID-19 pandemic and simulating natural disasters such as floods and earthquakes that may occur in the city, as well as making significant contributions to the infrastructure management of the city by developing a living model of the 26 million city of Shanghai with the data collected through satellites and drones. Digital twins in the energy; It finds its place in many purposes such as optimization of energy consumption in industrial processes, modeling of energy resources, designing energy storage systems.

In the energy sector, digital twins find a place for many purposes such as optimization of energy consumption in industrial processes, modeling of energy resources, and design of energy storage systems. Digital twin technologies are used in the design, development and improvement processes of smart energy systems in order to increase energy efficiency and sustainability in energy, and to reduce energy consumption and carbon footprint.

Final Remarks

Digital twin technology, which has the ability to create value in almost every sector, is an engineering field that requires interdisciplinary competence, where key technologies such as internet of things, artificial intelligence, simulation, optimization, edge computing, cloud computing, and big data are used jointly. With the inclusion of technologies such as augmented reality, mixed reality, blockchain, and quantum computing in this ecosystem, digital twins will gain a much wider and more active role in making sense of our present and shaping our tomorrow in the near future.

References

Bilgili, D., Kecibas, G., Besirova, C., Chehrehzad, M. R., Burun, G., Pehlivan, T., Uresin, U., Emekli, E., & Lazoglu, I. (2022). Tool flank wear prediction using high-frequency machine data from industrial edge device. Procedia CIRP, 118, 483–488. https://doi.org/10.1016/j.procir.2023.06.083

Cankal Altun, (2020). Akıllı Ev Cihazlarının Dijital İkizleri Üzerinden Sosyal Ve Bilişsel Beceriler Kazanarak Liberalleşmesi İçin Sis Bilişim Ve Dağıtık Hesap Defteri Teknolojisi Tabanlı Bir Mimari https://hdl.handle.net/20.500.11851/4074

Grieves, Michael. (2016). Origins of the Digital Twin Concept. 10.13140/RG.2.2.26367.61609.

Tao, F., Zhang, M., & Nee, A. Y. C. (2019). Background and Concept of Digital Twin. In Digital Twin Driven Smart Manufacturing (pp. 3–28).

Yu, W., Patros, P., Young, B., Klinac, E., & Walmsley, T. G. (2022). Energy digital twin technology for industrial energy management: Classification, challenges and future. Renewable and Sustainable Energy Reviews, 161(January), 112407. https://doi.org/10.1016/j.rser.2022.112407

https://www.nasa.gov/feature/50-years-ago-houston-we-ve-had-a-problem

https://blogs.sw.siemens.com/simcenter/apollo-13-the-first-digital-twin/

https://www.ge.com/research/offering/digital-twin-creation

https://www.shine.cn/news/metro/2203082846/

Writer : Gizem Burun