Industrial IoT (IIoT) in the Era of Digitalization

Industrial IoT (IIoT) in the Era of Digitalization

Industry is quickly embracing digitalization, which generates more and more industrial value through shared knowledge and growing foresight. Industrial Internet of Things (IIoT), one of the fundamental components of the digitalization era, opens the doors to a brand-new world where every process and object is more efficient, measurable, and controllable by connecting the various sensors around us to the internet. It is also an unavoidable technology for generating industrial value. The idea of connecting any gadget via the internet becomes the new norm of the future as IIoT finds its position in practically every area of modern technology.

Transformation in Manufacturing and Inception of IIoT

Internet was initially intended to be a network of connected computers for shared usage. The growing usage of personal computers and their integration into public networks has made the internet a form of public network that anybody may access. Moreover, microprocessor technology has advanced concurrently with sensor technology, and the variety of devices that can access the internet has grown. Due to the requirement to communicate with both other devices and bigger systems, it became necessary for devices to be able to connect to the internet.

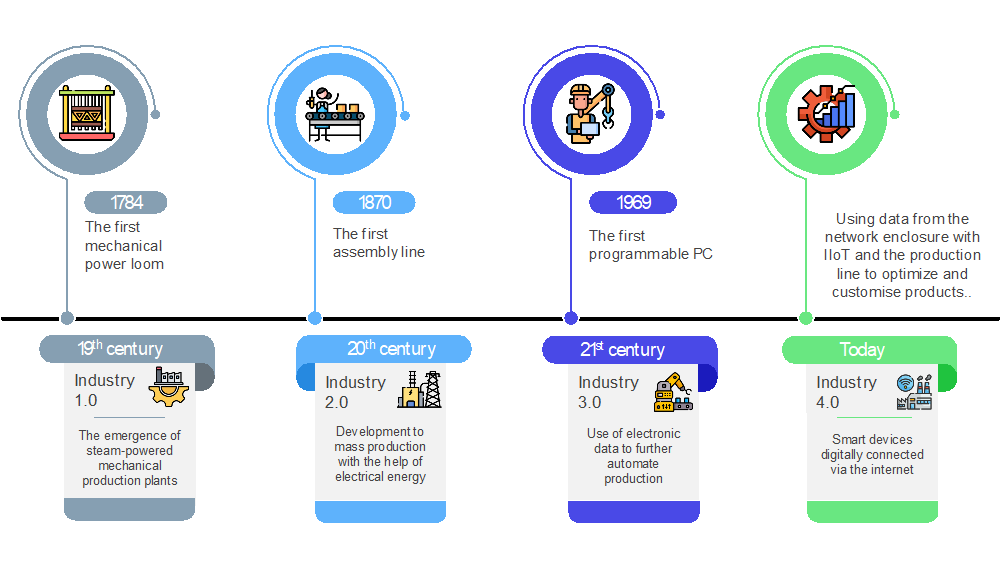

At MIT (Massachusetts Institute of Technology) in 1999, the idea of radio frequency technology identification networks was the forerunner of Internet of Things (IoT). The primary function of the developed system includes data collection, processing, transmission, and application of information. The term "IIoT" has become popular to describe the use of internet-connected devices, particularly in industry. IIoT technology and the shift from Industry 3.0 to Industry 4.0 manufacturing processes have been prompted by several technological advancements:

- Ubiquitous Connectivity: People can now interact constantly with one another through a variety of connections,

- Pervasive Digitization: With the widespread digitalization of goods and manufacturing procedures, the manufacturer and consumer can engage in a variety of interactions,

- Cloud Computing: Cloud computing allows businesses of all sizes to access powerful machines, the increasing rivalry between small and large businesses,

- Big Data Analytics: Real-time sensor data is transferred to big data clusters for analysis utilizing artificial intelligence,

- Social Networks: Social media allows people to share their experiences, which allows businesses to better understand their customers and cater to their requirements,

- Smart Sensor Network: As sensor costs fall, their use in daily life rises, and as a result of the data collected from them, both the products and the production methods continue to advance.

What are the Benefits of IIoT?

The information gathered by internet-connected devices can be utilized to improve productivity, enable real-time decision-making, create quick fixes for pressing issues, offer emergency answers, and deliver novel experiences.

IIoT has an impact on both the individual's and the organization's current business and lifestyle because it is a quickly emerging technology. Utilizing integrated business processes and production line equipment can boost efficiency. With the use of IIoT devices, for instance, a production line machine failure might be identified and avoided before any additional faulty goods are produced. Also, Security measures can be performed to prevent the release of toxic substances with IIoT devices sensitive to smoke, fire, or chemical compounds. Similarly, product quality can increase as the line's mistake rate will drop as IIoT reduces human interaction on the manufacturing line. Moreover, with the use of devices that track user compliance in real-time, consumer needs may be properly assessed, and user-based customized solutions can be made available.

Problems to be Overcome, Deficiencies to be Corrected

To enable end-to-end collaboration using data successfully, new obstacles are encountered as more and more devices connect, and new solutions are required. The requirement for an architectural design that enables these devices to communicate, connect, control, and interact across applications is driven by the growth of smart devices and the reality that billions of IIoT devices can connect to the internet. The techniques required to analyze and convert the vast amounts of raw data produced by IIoT technology into useful information should also be distinct from those used for traditional data analysis.

Although sensor-based systems are often closed systems, many devices will need to talk to one another in the future. For instance, the increased usage of autonomous package carrier robots in workplaces necessitates communication between these machines to prevent accidents. In addition to addressing these needs, "openness," "functionality," and "security" should be balanced. Furthermore, for IIoT devices to communicate with one another, they need to be synced, know where they are and have consistent settings for things like sleep and waking hours.

Future Trends

- Fewer people would be involved in the production process. Products, therefore, will be produced more individually and with fewer flaws through IIoT.

- IIoT will enhance not only certain items but also an entire production line. (Both processes will be improved, and the caliber of the delivered goods and services will rise.)

- With IIoT, personalized goods can be more prevalent.

- Microsensors and IoT devices can be used to track employee health and workplace accidents in terms of occupational safety.

- Connecting vehicles to each other and to other smart devices (vehicle-2-anything) via IIoT devices in smart cars can make vehicle traffic in the manufacturing area safer.